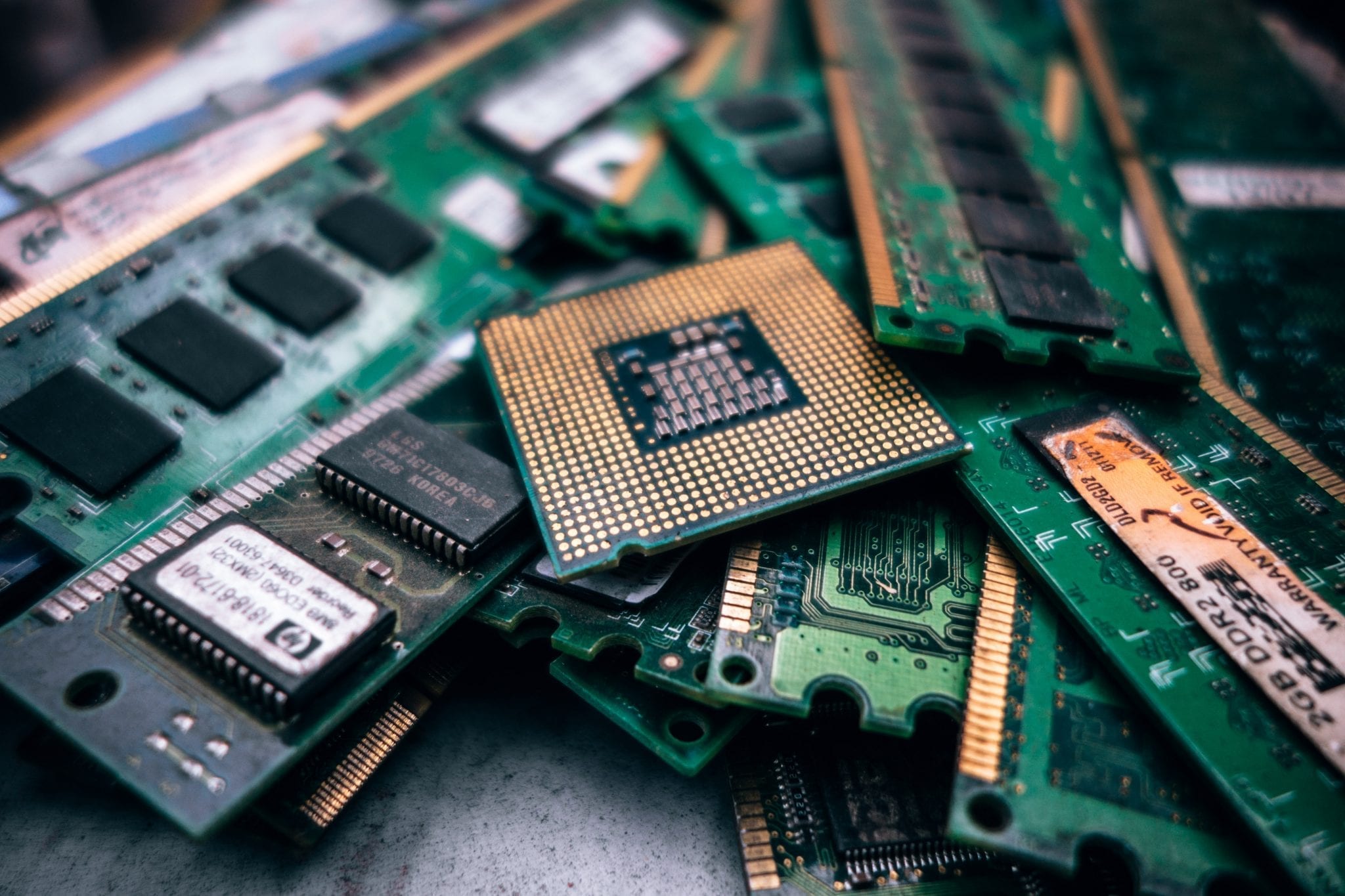

On Episode 73 of The Edge of Innovation, we’re talking with entrepreneur Simon Wainwright, president of Freebird Semiconductor, about solving power management problems with emerging technologies.

Hacking the Future of Business!

On Episode 73 of The Edge of Innovation, we’re talking with entrepreneur Simon Wainwright, president of Freebird Semiconductor, about solving power management problems with emerging technologies.

On Episode 72 of The Edge of Innovation, we’re talking with entrepreneur Simon Wainwright, president of Freebird Semiconductor, about Gallium Nitride technology and the future of the space industry.

On Episode 71 of The Edge of Innovation, we’re talking with entrepreneur Simon Wainwright, president of Freebird Semiconductor, about how he started a company to manufacture semiconductors using GaN technology!

On Episode 63 of The Edge of Innovation, we’re talking with entrepreneur Greg Arnette, about some of the latest tech trends and gadgets that are on our radar.